SOLARCYCLE introduced a breakthrough in photo voltaic circularity with the profitable growth of a proof-of-concept photo voltaic panel made with 50% recycled glass from end-of-life photo voltaic panels.

SOLARCYCLE introduced a breakthrough in photo voltaic circularity with the profitable growth of a proof-of-concept photo voltaic panel made with 50% recycled glass from end-of-life photo voltaic panels.

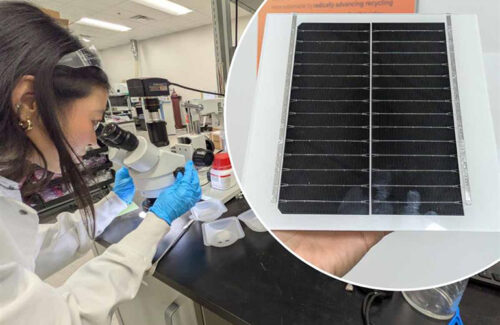

The demonstration panel, or “mini module,” was developed in partnership with Arizona State College’s Ira A. Fulton Colleges of Engineering. Led by Zachary Holman, Vice Dean for Analysis and Innovation, the mission examined the efficiency potential of photo voltaic panels constructed with specialised recycled glass. The analysis demonstrated that panels made with recycled photo voltaic glass matched the efficiency of these made with conventional supplies, marking a important step towards a closed-loop photo voltaic manufacturing course of.

ASU researcher Kate Fisher fabricated baseline mini modules utilizing industrial virgin photo voltaic glass and take a look at mini modules utilizing a 50/50 mix of virgin supplies and recycled glass cullet from end-of-life photo voltaic panels that had been processed by way of SOLARCYCLE’s proprietary recycling expertise. Utilizing industry-standard power-conversion effectivity checks, researchers evaluated each units of modules and located that the modules constructed with recycled glass carried out in addition to these made with virgin glass, with no statistically important variations throughout any key metrics.

“That is precisely the type of consequence we hope for when {industry} and academia collaborate,” stated Dr. Holman. “Collectively, we proved that you simply don’t must sacrifice efficiency to construct photo voltaic panels extra sustainably. It’s not only a lab success — it’s a path ahead for the {industry}.”

These mini module checks help SOLARCYCLE’s broader mission to shut the loop in photo voltaic panel manufacturing, scale back photo voltaic waste and strengthen the home photo voltaic provide chain. SOLARCYCLE plans to construct a photo voltaic glass manufacturing unit adjoining to its recycling facility in Cedartown, Georgia. There, it will likely be the primary on the planet to make use of recycled cullet as a key enter.

“By proving we are able to manufacture new photo voltaic panels utilizing recycled supplies that produce at peak efficiency ranges, we’re taking a serious step towards making the photo voltaic {industry} extra sustainable, scalable and self-reliant,” stated Pablo Dias, chief expertise officer and co-founder at SOLARCYCLE. “Pushing the envelope in innovation is core to our mission and this achievement exhibits why.”

This proof-of-concept analysis is one in every of dozens of patented developments from SOLARCYCLE. The corporate has constructed one of many world’s high photo voltaic recycling analysis and growth groups, with greater than 30 engineers and scientists throughout the U.S., Brazil and China. It companions with world-class establishments like Arizona State College to speed up analysis and develop its expertise pipeline.

Information merchandise from SOLARCYCLE